An easy and cost effective way of removing the discolouration from TIG (also called Gas tungsten arc welding – GTAW), MIG ( Metal Inert Gas, also called Gas Metal Arc Welding – GMAW) WIG Orbital welding and Plasma Arc Welding (developed from GTAW welding) plasma cutting without dulling the parent metal.

How to easy clean and passivate in one operation

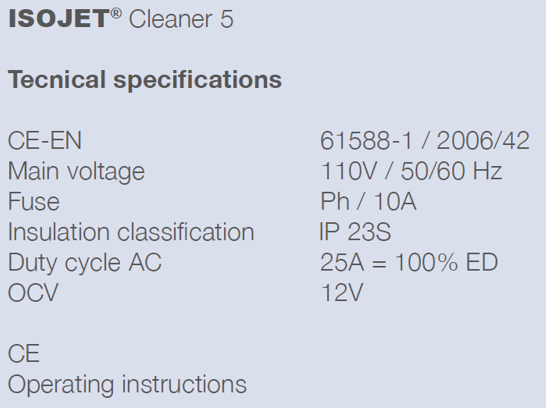

- Connect clamp to stainless steel part with the weld to be cleaned.

- Connect brush arm to current supply, attach carbon brush to the contact arm..

- Dip carbon brush into the electrolyte (ISOL C or ISOL nature and brush over weld once or twice)

The carbon brush will adjust to all weld shapes in all positions: flat, external or internal corners

Oxidation is removed instantly without leaving haloes

After cleaning:-

- Rinse the stainless steel surface to remove any remaining ferrous contamination.

- Thoroughly clean the brush in water to remove all metal residues which could cause corrosion later.

Although the cleaned surface is passivated we recommend applying a coat of ISOJET MCT 800 providing an excellent surface protection and a stunning shining surface against future contamination.

For immediate passivation and the removal of any brown edges apply SURFINOX fluid.

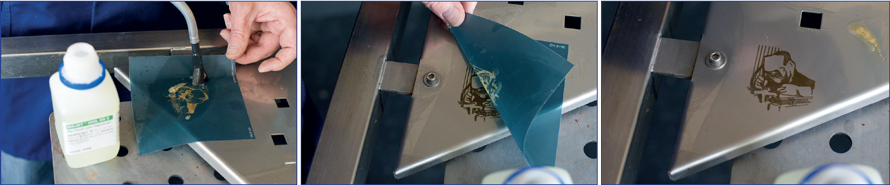

How to etch

- Connect clamp to stainless steel part with the weld to be cleaned.

- Connect brush arm to current supply, attach carbon brush to the contact arm..

- Dip carbon brush into ISOL ES.

- Brush several times over a pre made stencil to etch the stainless steel surface.

Stencils can be used up to 200 times.

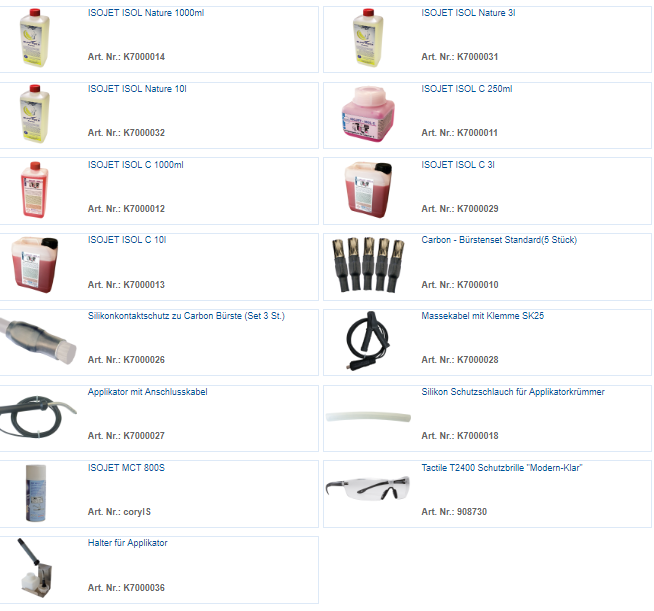

Spare Parts / Accessories

Technical Specification